Process resources

Implementing RFID in the Automotive Supply Chain

This recommendation aims to help the automotive industry, project leaders and users, and external technology integrators or vendors to implement RFID processes across different partners of the supply chain, in order to obtain good interoperability and avoid multiple solutions that could become a blocking point for industry suppliers.

The document covers different logistics and supply chain use cases, some of which are described in more detail in related annexes. It focuses on issues which contribute to defining common standards for a better interoperability between the partners involved.In terms of technology, many contactless radio frequency technologies are available and can justly be applied in specific use cases. In order to simplify the recommendations, this document focuses on Passive UHF (Ultra High Frequency) RFID technology.

RFID for Tracking of Parts and Assemblies

This Odette recommendation describes the processes and methods of tracking and tracing of vehicle parts and enabling the authentication of original parts using RFID technology. It has been developed to move towards achieving widespread standardisation of RFID component usage, tag data storage and RFID technology implementation across supply chains.

RFID in Vehicle Distribution Processes

This Odette recommendation describes the processes and methods of tracking and tracing vehicles in the distribution processes from factory to dealer using RFID technology and a smart label. It has been developed to move towards achieving widespread standardisation of RFID component usage, tag data storage and RFID technology implementation across vehicle distribution chains.

Returnable Transport Items Identification

Version 3 published March 2021. RFID technology has been widely adopted by the automotive industry in individual organisations due to the efficiency and security gains it delivers. However, widespread use between companies is currently much rarer due to compatibility issues. In response to this, Odette, AIAG, JAMA and JAPIA have jointly developed recommendations for RFID use in Returnable Transport Items Identification. The aim is to help moves toward the creation of general purpose global guidelines and accelerate further international adoption of RFID solutions.

RFID Item Level Standard

Version 3 published March 2021. This Radio Frequency Identification (RFID) Item Level Standard describes best practices, processes, and methods for item identification, verification, traceability, product characteristics, and Vehicle Identification Number (VIN) throughout the global automotive supply chain. Extensive efforts have been made by the automotive industry to incorporate interchangeable data use between 2D optical symbols and electronic media such as RFID. This publication gives standards for the implementation and use of RFID in such applications and was jointly produced by Odette, AIAG, JAMA and JAPIA.

Capturing Supply Chain Events with auto-ID

To achieve process transparency, machine-readable objects and ways of tracking these objects along the process chain need to be defined and implemented. The Odette Recommendations LR01, LR02, LR03, LR04 and LR05 outlined the foundations and the next logical step is the implementation of standardised communication with all business partners across company boundaries, based on international standards he Odette Recommendation “Capturing Supply Chain Events with auto-ID” addresses this issue.

Global Transport Label - Odette Profile

(previously published as European Profile)

Members of the JAIF combined the best features from their own label standards – including ISO 15394, ANSI MH10.8.1, the Odette Transport Label and the AIAG B-10 to produce a standard Global Transport Label which includes features such as the ISO “Licence plate,” Linear Bar Code 128 and 2D Data Matrix, QR Code and PDF417. Based on this standard, an Odette profile has been further developed and maintained.

VIN Labels in the Vehicle Distribution Process

Developed by Odette and ECG, this recommendation has the following objectives:

- Define a standard location and fixing method for the vehicle identification label

- Recommend a size and layout for the vehicle identification label

- Define a minimum content for the vehicle identification label

- Recommend a bar-coding standard

- Provide recommendations for the quality of the vehicle identification label

Global Transport Label

This document details common Global Transportation Label standards on container-labelling for use by suppliers and customers, and has been updated to include Data Matrix and QR code 2D symbologies. It was developed by collaboration between the members of Odette, AIAG and JAMA automotive associations representing more than 80% of worldwide production.

Odette Transport Label - Large (OTL1)

This is the original A5 Odette Transport Label (210mm x 102mm) which is designed to be used on product packaging units and transport packaging units sent between supplier and customer. First introduced in the 1980s, this label spec has been updated several times and is still in widespread use in the automotive industry today.

Odette Transport Label - Small (OTL3)

This Odette label (210mm x 74mm) was introduced to allow its use on smaller units where the original A5 label was too large. It also allows for the inclusion of additional logistics information to facilitate the automated movement of product packaging units from warehouse to trackside.

Automotive Supply Chain API for Transport Track & Trace

Describes how to define and implement standardised REST-API interfaces for the collection and provision of discrete pieces of information supporting logistics activities in the automotive supply chain.

It includes a data model and functionality for the use of REST-API in transport processes as an extension to established EDI data exchange processes.

Odette Purchase Order Message

EDI Implementation Guideline

ORDERR

Based on EDIFACT ORDERS D.05B - Syntax v4

Odette Purchase Order Change Message

EDI Implementation Guideline

ORDCHG

Based on EDIFACT ORDCHG D.05B - Syntax v4

Odette Purchase Order Response Message

EDI Implementation Guideline

REPORD

Based on EDIFACT ORDRSP D.05B - Syntax v4

Odette Price List Message

EDI Implementation Guideline

PRILST

Based on EDIFACT PRICAT D.96A - Syntax v4

Joint Automotive Delivery Forecast Message

EDI Implementation Guideline

DELFOR

Based on EDIFACT D.04A - Syntax v4

(File must be opened with Adobe Acrobat to access attachments)

Joint Automotive JIT Delivery Instructions Message

EDI Implementation Guideline

DELJIT

Based on EDIFACT D.18A - Syntax v4

(File must be opened with Adobe Acrobat to access attachments)

Odette Delivery Schedule Message

EDI Implementation Guideline

DELINS

Based on EDIFACT DELFOR D.96A - Syntax v4

Odette Schedule Exception Handling Message

EDI Implementation Guideline

EXHAND-EXHRSP

Based on EDIFACT DELFOR D.04A - Syntax v4

Odette Call-Off Delivery Message

EDI Implementation Guideline

CALDEL

Based on EDIFACT DELJIT D.98B - Syntax v4

Odette Synchronised Delivery Message

EDI Implementation Guideline

SYNCRO

Based on EDIFACT DELJIT D.03A - Syntax v4

Odette KANBAN Delivery Message

EDI Implementation Guideline

KANBAN

Based on EDIFACT DELJIT D.96A - Syntax v4

Joint Automotive Despatch Advice Message

EDI Implementation Guideline

DESADV

Based on EDIFACT D.20B

(File must be opened with Adobe Acrobat to access attachments)

Odette Despatch Advice Message

EDI Implementation Guideline

AVIEXP

Based on EDIFACT DESADV D.96A - Syntax v4

Joint Automotive Receiving Advice Message

EDI Implementation Guideline

RECADV

Based on EDIFACT D.07A - Syntax v4

(File must be opened with Adobe Acrobat to access attachments)

Managing Inbound Transport with Mobile Apps

The recommendation describes a standard model for the exchange of data between the yard management systems of the plants and the transport management system of the transport service providers. Based on this recommendation, application developers will be able to develop and programme the various IT systems in such a way that the requirements for the operational control of transport in the arrival area are supported uniformly across all apps.

Odette Battery Data Exchange Message

EDI Implementation Guideline

PRODAT

Based on UN D.21A S4 - S3 Profile (Part 11)

Unique Parts Identification

To accurately trace parts and components they should be clearly and easily identified using unique codes. This Odette recommendation provides details on how to implement and use Unique Part Identity (UPI) codes – one for each specific component – to achieve this. It explains how they can be used on safety components and enable access to the industrial history of a part or group of parts in component databases.

Traceability of Vehicle Components

The extended supply chains of automotive businesses require accurate and efficient traceability of parts and components across several layers. But to ensure that components can be traced properly throughout different organisations and systems, an element of standardisation of tracking processes is needed. This document includes a variety of standardised processes for implementing component traceability and identifying technical specifications.

Vendor Managed Inventory (VMI)

This Odette recommendation has been developed to assist suppliers in the management of inventory production. The Vendor Managed Inventory (VMI) process explains how suppliers can efficiently analyse inventories and maintain production levels between set maximum and minimum amounts. This can bring significant benefits by reducing administration and logistics costs whilst ensuring the on-going security of supplies.

Collaboration Managed Inventory (CMI) Minimum/Maximum

Based on Odette’s Vendor Managed Inventory (VMI) and AIAG’s Inventory Visibility and Interoperability Min/Max Replenishment Business Process Future State (IBP-1), this recommendation explains how significant cost savings can be achieved by implementing Collaboratively Managed Inventory (CMI) Min/Max processes. Using CMI Min/Max leads to increased visibility between suppliers and customers and to a reduction in administration and transport costs.

Joint Automotive Invoice Message

EDI Implementation Guideline

INVOIC

Based on EDIFACT D.07A - Syntax v4

Odette Invoice Message

EDI Implementation Guideline

INVOIC

Based on EDIFACT INVOIC D.03A - Syntax v4

Odette Statement of Account Message

EDI Implementation Guideline

STATAC

Based on EDIFACT STATAC D.96A - Syntax v4

Joint Automotive Remittance Advice Message

EDI Implementation Guideline

REMADV

Based on EDIFACT D.04A - Syntax v4

(File must be opened with Adobe Acrobat to access attachments)

Odette Remittance Advice Message

EDI Implementation Guideline

REMADV

Based on EDIFACT REMADV D.96A - Syntax v4

Automotive Packaging Manufacture - Capability Assessment

Describes the process of auditing manufacturers of reusable and disposable packaging items for use in the automotive supply chain.

Its purpose is to provide a guideline for customers who want their packaging manufacturers to improve their processes and to establish a common definition of best practices to facilitate efficient physical and information flows between customers and packaging manufacturers.

This recommendation includes an excel based audit tool that enables a comprehensive evaluation of packaging manufacturers capability.

Production Capacity Assessment Tool

The Production Capacity Assessment Tool detailed in this document is recommended as the preferred, proactive risk management methodology for checking the planned and actual capacity of a production facility. The Tool offers the advantage of standardising all of the business parameters that are necessary to calculate production capacity.

Supply Chain Risk Management

This guideline has been developed to provide practical advice and guidance in the use of existing, proven techniques to identify, measure, monitor, mitigate and manage supply chain risk by both large and small organisations, whatever their level in the supply chain.

Vehicle manufacturers and Tier 1 suppliers who already have well developed SCRM processes and plans in place will be able to compare themselves with industry best practice contained in this guideline.

It is also aimed at those organisations that do not currently have robust SCRM processes in place, or have not yet started implementing SCRM and are seeking to have a better understanding of the processes involved and need support to identify a practical starting point.

Collaborative Forecasting

Forecast accuracy is a fundamental requirement for the alignment of manufacturing and logistics processes throughout the supply chain, involving OEMs, suppliers, and transport and logistics providers. This Odette Best Practice recommendation defines a methodology for measuring the forecast accuracy of customer schedules.

This measurement is essential to support improvement initiatives that can simultaneously increase service levels and reduce inventory, both at the customer side and the supplier side The Guidelines list the data to be collected and the mathematical approach to calculating the Forecast Accuracy Index (FAI) and an associated Weighted Tracking Signal (WTS).

Logistics Capability Evaluation Tool for LSPs

This tool has been created to help organisations develop and implement a world class Materials Planning and Logistics Management system. It consists of a set of recommendations and best practices that can be used by Logistics Service Providers (LSPs) to move towards establishing a common international approach to assessing best practices.

Demand Capacity Planning

Demanding supply chains require efficient and comprehensive management processes to avoid capacity shortfalls and the under-utilisation of resources. Demand Capacity Planning (DCP) plays a significant role in this area, by incorporating business process models, functionalities and respective data elements.

This publication defines standards for successful DCP in the automotive industry including a basis for the interoperability of applications from different software providers.

Odette Deviation Report Message

XML Implementation Guideline

The XML message specified in this publication provides a means for a customer in the Automotive Supply Chain to transmit a report of a Logistics Catalogue Deviation to a supplier electronically as recommended in the Odette/AIAG Recommendation ‘KPIs for Automotive Supply Chain Management (LK03)’.

Odette Delivery Accuracy Report Message

XML Implementation Guideline

The XML message specified in this publication provides a means for a customer in the Automotive Supply Chain to transmit a report of a Delivery Accuracy Rating to a supplier electronically as recommended in the Odette/AIAG Recommendation ‘KPIs for Automotive Supply Chain Management (LK03)’.

Suppliers Long Term Declaration Message

XML Implementation Guideline

Specifies a data exchange procedure and structured format for the transmission of supplier declarations to customers concerning the origin of the parts they are supplying The declaration in the form of an XML message can be processed automatically in the customer system.

Includes XML Guideline, XML Schema file and associated technical artefacts and business rules for the use of the XML Suppliers Long Term Declaration as well as examples visualised as forms.

Digitalisation of Finished Vehicle Logistics

This Recommendation covers typical logistics and service processes undertaken in the distribution of finished vehicles between vehicle manufacturers and their dealerships or other end customers. It specifies standard electronic messages for automated data exchange between vehicle manufacturers (or other shippers) and providers of logistic services. These logistics services can include transport, storage, maintenance, repair and any other actions that may be required during the movement of vehicles from the manufacturer to the dealership.

A set of messages associated with this Recommendation has been developed to cover all communication processes currently defined as being required between partners (vehicle shippers and logistics service providers) in the Finished Vehicle distribution chain.

The Transport Capacity Reservation process was added in Version 1.2

FVL EDIFACT Messages

EDI Implementation Guidelines

A suite of 12 EDIFACT messages have been developed jointly by ECG, Odette and VDA to cover the entire outbound logistics processes as described in the Finished Vehicle Logistics Process Description (FV00). The publication also includes example use cases and sample messages for each logistics process.

FVL Vehicle Damage Report Message

XML Implementation Guideline

Sent to communicate damage information from the LSP to the OEM.

Odette Transport Status Report Message

EDI Implementation Guideline

IFTSTA

Based on EDIFACT IFTSTA D.20B

Packaging Management Guidelines

This recommendation defines the essential preconditions for efficient packaging management such as master data management as well as pool installation and maintenance.

It also describes the core operational processes such as packaging agreement, packaging accounting and the empty packaging supply chain.

As each partner has their own system solution, whether using standard or proprietary software, the focus of this recommendation is the description of common process patterns which enable the use of standardised messages in the information exchange between partners.

Joint Automotive Inventory Report Message

EDI Implementation Guideline

INVRPT

Based on EDIFACT D.13A - Syntax v4

(File must be opened with Adobe Acrobat to access attachments)

Empty Packaging Order Message Family

The Empty Packaging Order family of messages includes the Order Proposal, the Order, Order Change and Order Response. An introduction to the empty packaging order process is also provided.

Empty Packaging Transport Order Message Family

The Empty Packaging Transport Order family of messages is split into 2 options. One option is based on using the DESADV message (widely used in the automotive industry) to order transport, the other option is based on IFTxxx messages (used by the transport industry). Users can decide which option is more suited to their own operations and those of their partners.

Empty Packaging Despatch Message Family

The Empty Packaging Despatch family of messages includes the advance notification of packaging delivery and the actual despatch advice. An introduction to the Empty Packaging Despatch process is also included.

Empty Packaging Despatch Message Family

The Empty Packaging Despatch family of messages includes the advance notification of packaging delivery and the actual despatch advice. An introduction to the Empty Packaging Despatch process is also included.

Empty Packaging Despatch Message Family

The Empty Packaging Despatch family of messages includes the advance notification of packaging delivery and the actual despatch advice. An introduction to the Empty Packaging Despatch process is also included.

Odette Application Error and Acknowledgement

EDI Implementation Guideline

APERAK

Based on EDIFACT APERAK D.08A - Syntax v4

This message supports automated error handling for incoming EDI messages such as Despatch Advice or Invoice, including:

- Acknowledgement of receipt of the incoming message

- Reporting of syntax errors which prevent further processing.

- Reporting of actual data errors

JAIF Data Identifiers for Use in AutoID

The JAIF* has created a separate table of the ANSI MH10.8.2 Data Identifiers that are actually in use in automotive AutoID applications or are referenced in the various AutoID Recommendations that have been published, either jointly or independently, by JAIF members.

The table of JAIF Data Identifiers is a subset of the full list of Data Identifiers specified in the Data Identifiers standard ANSI MH10.8.2 which is published and maintained by the MH10 Committee for Unit Loads and Transport Packages of MHI.

* Joint Automotive Industry Forum = AIAG, JAMA/JAPIA and Odette

Forecast Accuracy Measurement

The market for automotive spare parts is highly dynamic and volatile, and presents significant challenges to both manufacturers and suppliers in maintaining service and inventory levels Effective forecasting in this area is vital for increasing supply chain performance, and this Odette publication has been developed to provide a standardised method for measuring forecast accuracy, based on an in-depth industry study.

Reporting Freight Greenhouse Gas Emissions

These Guidelines have been published by Odette specifically for the automotive sector. They are directed at helping all those involved to understand the principles and to adopt a consistent approach that will support both recent and future standards and legislative requirements. Rather than introducing new methodologies, these Guidelines make recommendations based on use of the most appropriate existing initiatives.

Key Performance Indicators for LSPs

All organisations know that maintaining logistics performance is vital for an effective supply chain – but this can only be achieved when suppliers at all levels have consistent measurements of good performance in place. To help achieve this, Odette has produced this set of common definitions of standardised KPIs for measuring logistics performance that can help improve efficiency and decrease costs across the supply chain.

Key Performance Indicators for Automotive Supply Chain Management

Originally serving as a supplemental product to the Global MMOG/LE tool, this recommendation defines standard key performance indicators (KPIs) for global supply chain management in the automotive industry. These common indicators not only align with the requirements of Global MMOG/LE, but also help facilitate greater understanding between business partners and support risk management. This KPI document provides greater transparency between OEM and supplier performance expectations.

Automotive Packaging Manufacture - Key Performance Indicators

Defines key performance indicators (KPIs) and a performance evaluation process for packaging manufacturers who are responsible for the production of durable and expendable packaging items for automotive manufacturers.

Using this recommendation, a company can fulfil internal objectives while using indicators common to the industry that are better understood by packaging manufacturers and their customers.

The KPIs specified in this recommendation should form the basis for a performance measurement system but customers may specify additional criteria to be used for their own evaluation of packaging manufacturers.

Key Performance Indicators for Finished Vehicle Logistics

Provides a consolidation of existing and new KPIs for use between OEMs and logistics service providers involved in the transport of the finished vehicles and their interim storage during the transport process.

Includes a definition of 9 indicators (objectives, scope, how to measure) and a description of application and communication conditions.

Digitalising the Part Packaging Agreement

Guideline covering the part packaging agreement process between customers and suppliers and addressing issues of packaging master data and packaging agreements including:

• Returnable packaging, disposable packaging, packaging aids and accessories

• Packaging of production parts, components, raw materials, assemblies

• Packaging of aftermarket and service parts

Download includes:

OM48 Packaging Master Data

OM49 Packaging Data Sheet

OM50 Packaging Data Code Lists

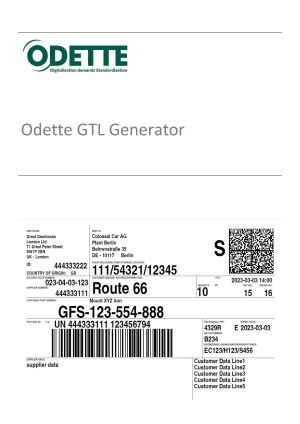

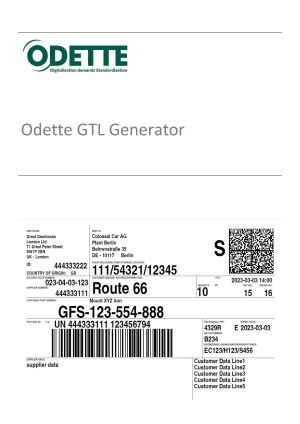

Odette GTL Generator (Windows)

Tool provided by Odette to generate Global Transport Labels (Odette Profile) that meet the standard Odette LL08 (VDA 4994).

Sizes currently supported:

A5 (210mm x 148mm)

A6 (148mm x 105mm)

SLC1 (210mm x 74mm)

Contact us if you require any additional sizes that are specified in LL08.

Odette GTL Generator (Linux)

Tool provided by Odette to generate Global Transport Labels (Odette Profile) that meet the standard Odette LL08 (VDA 4994).

Sizes currently supported:

A5 (210mm x 148mm)

A6 (148mm x 105mm)

SLC1 (210mm x 74mm)

Contact us if you require any additional sizes that are specified in LL08.

Invoice Viewer & Converter

Tool provided by Odette. Can take invoices which have been created in accordance with EN 16931 and display them in a human-readable format. Any invoices which were originally created using the OASIS UBL format are converted to the CEFACT Cross Industry Invoice (CII) format.